150 Years And Still Going Strong: How Bacardi Rum Is Made

Bacardi uses blackstrap molasses to make its rum. Years ago the molasses was sourced from local sugar cane, but in the 1980s the sugar cane in Puerto Rico dried up. Nowadays, scouts are sent around the world to places like Fiji, Hawaii, and Brazil to find the best molasses for use in Bacardi rum.

Diluting the Molasses and Adding Yeast

Molasses is diluted with filtered water and then married with a strain of yeast dating back to 1862. This specialized yeast is what gives Bacardi its unique flavor. Any other yeast used in this process would change the entire flavor profile of the rum. Here is a beaker of diluted molasses next to a beaker of molasses that had been fermented for 10 hours. A slightly bitter flavor had started to develop as the yeast consumed the sugar.

50,000-Gallon Tanks

These are the 50,000-gallon tanks used for fermentation. The process is periodically analyzed with a hydrometer to check the sugar levels until the yeast has consumed all of the sugar in the molasses.

Monitoring the Tanks

The temperatures of the tanks are closely monitored throughout the fermentation process to ensure that they remain stable. Fifty-thousand gallons of molasses are completely fermented in less than 30 hours.

Parallel Distillation

Bacardi utilizes a parallel distillation process using column distillation, and the fermented mixture is actually distilled twice. The first liquor is stronger in flavor and is later used for heavy-body rums. The mixture is then re-distilled to create a lighter-bodied liquor. Through this step of distillation, all rums are essentially the same and gain additional character through aging and blending.

Charcoal Filtration

Charcoal filtration is one of the revolutionary steps that Don Facundo initiated with his rum. It is used to remove impurities and control the flavor. In many cases, charcoal filtration is used both before and after aging. It can also be used to remove the color from the rum after aging to create clear rum, such as Bacardi Superior.

Aging in Oak Barrels

All Bacardi rum is aged in American white oak whiskey barrels. The barrels are all previously used for aging whiskey and are then steam-cleaned and toasted according to the rum blender's specifications. If fresh barrels were used instead, the rum would taste more like whiskey than rum. Rums are then aged for at least one year depending on the type of rum. Spirits mature and age faster in the Caribbean because of the climate, so a rum may be younger but more mature than an older Scotch because they mature two to three times faster in the Caribbean than they would in Scotland, for example.

Blending

The final step in making Bacardi rum is blending. Highly trained master blenders call on their senses of sight, smell, and taste to blend rums from many different barrels to create each Bacardi variety. Blending is an art, not a science.

Tested and Approved

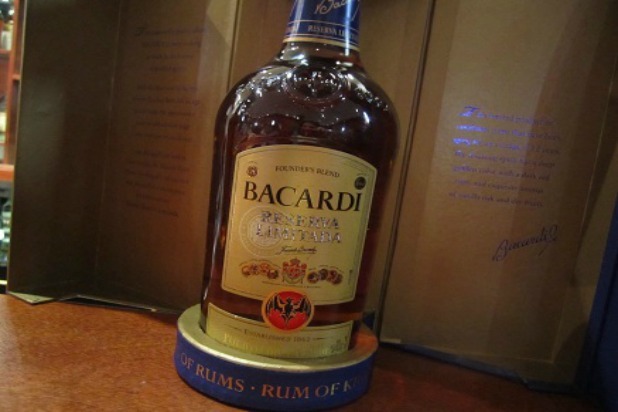

Once the rums are blended, they must be tested and approved by a quality control lab and a panel of tasters before they are exported from the distillery to be bottled and sold. This bottle of Bacardi Reserva Limitada will be available soon in the United States; it has been aged 10 years and retails for $110.

Expansion

Bacardi is currently laying the groundwork for a major expansion in the coming years. When construction is completed, visiting Casa Bacardi will be an even more riveting experience, as visitors will be able to see more of the history and the rum-making process. Admission to Casa Bacardi is always free for visitors.