We Finally Know Why Canned Food Containers Are Always Ribbed

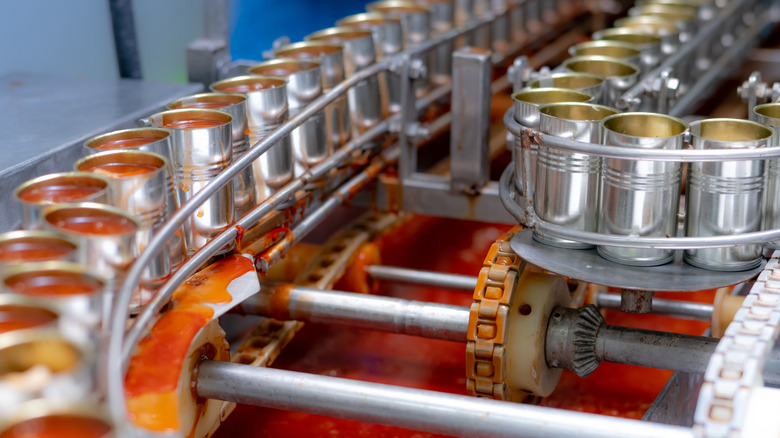

Steel and tin cans have been around for more than 200 years, greatly improving the packaging logistics of goods the world over. Food was being canned almost immediately upon the creation of the tin can, and the advancements in technology have made the process much safer and cheaper over the centuries. Now, you can find many types of canned food, from applesauce to oysters and peas.

Looking at the walls of a canned food container, you may wonder why many of them are ribbed. Some cans may be more densely ribbed than others, and some may not even have ribs at all. But many cans have ribbing to some degree. There's a simple reason for this: it makes the can stronger. Proving this is equally simple; an average person could crush an empty straight-walled can but would have a heck of a time trying to do the same to an empty corrugated can.

Why do the cans need to be stronger? One of the most practical reasons is that it helps during transportation. Cans need to endure all that handling, movement, and stacking, and the added strength that the ribs provide helps ensure the cans don't burst or collapse under weight. Food items that tend to be stored for longer or are generally heavier have ribbed cans that can withstand these different factors.

Giving it all room to expand and contract

Many kinds of food need to be heated when they are being canned. This is done for various reasons, including cooking the food itself (think canned seafood or soup). However, the most important reason for heating the cans is to rid both the container and its contents of germs, essentially sterilizing it. This is the main contributing factor to the longevity of canned food, as many of them have "best by" dates further into the future than their plastic counterparts.

What do the ribs on the cans have to do with heating? The ribbing adds surface area to the can without necessarily adding height or width. Think of the bendy part of a straw: when it's compressed, the straw is significantly shorter than if you stretched the flexible part out completely. Many elements and alloys expand or contract depending on the temperature, and the ribs help the cans do just that without the walls losing their structural integrity and splitting apart. If you've looked at warped and cracked infrastructure like roads, the same thing can happen on a smaller scale to a can. When canned food containers heat up, especially during transport, the ribs help them expand and contract more safely. Without these ribs, cracks in the can wall happen more easily. These cracks may not be felt (or seen) but may allow bacteria into the interior of the can, raising the risks of botulism.

As always: recycle, recycle, recycle

As we've discussed, the two main reasons for the ribbing on canned food containers are to increase their strength and help them expand and contract during processing and according to the ambient environment. Conversely, there are canned food containers that don't have ribs at all, like those for beverages and smaller cans of seafood. This is because these items either do not require the same heat treatment or are of a size short enough that the heat will not adversely affect them like it would taller cans and will still stack well.

As a consumer, one of the best reasons to choose steel or tin cans when purchasing packaged food is that these cans are recyclable, especially those made of aluminum. If you're worried about the flavor, it's possible to eliminate that "canned" taste, especially with vegetables.

When you've emptied your cans of food, remember to rinse them out and drop them off at your nearest recycling center. Some recycling programs even give you cash rebates for recycling as an incentive — perfect to add back to your grocery budget.