Chocolate From Tree To Bar At Rabot Estate, St. Lucia (Slideshow)

Cocoa pods are cut from the tree when they're bright yellow, after growing for a period of four to five months. The pod on the left is ripe; the pod on the right, unripe.

2. Extract the cocoa seeds from the cocoa pulp

Cocoa pulp, the juicy white membrane surrounding each seed, is edible. Hotel Chocolat's St. Lucia location restaurant Boucan makes a fizzy sweet-tart cacao Bellini cocktail using the meringue-like pulp.

3. Ferment, dry, and roast the cocoa beans

After being removed from the pod, cocoa beans are fermented for up to a week and sun-dried for up to two weeks. To make chocolate, they are then roasted and winnowed, which removes the shell. The resulting pieces are called cocoa nibs.

4. Grind the beans with a mortar and pestle

In the first step of forming the chocolate bar, cocoa nibs are ground by hand with a mortar and pestle.

5. Achieve a finely ground cocoa paste

Once finely ground, the cocoa nibs are ready to become "chocolate liquor."

5. Achieve a finely ground cocoa paste

Once finely ground, the cocoa nibs are ready to become "chocolate liquor."

6. Add cocoa butter

Cocoa butter, the fatty solids obtained from whole cocoa beans, is added.

7. Mix the nibs with the butter until smooth

With the addition of cocoa butter, the "chocolate liquor" achieves a silky, smooth texture.

8. Add confectioners' sugar

Confectioners' sugar is added to sweeten the still bitter mixture and smooth the texture further.

9. Pipe the chocolate into a mold

Lastly, the sweetened chocolate liquor is poured into a pastry bag and piped into a mold.

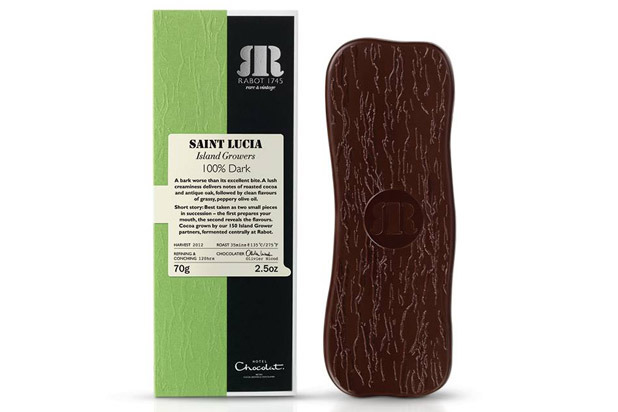

10. Finished chocolate bar

After chilling in the refrigerator for 30 minutes, the finished bar is ready to eat.